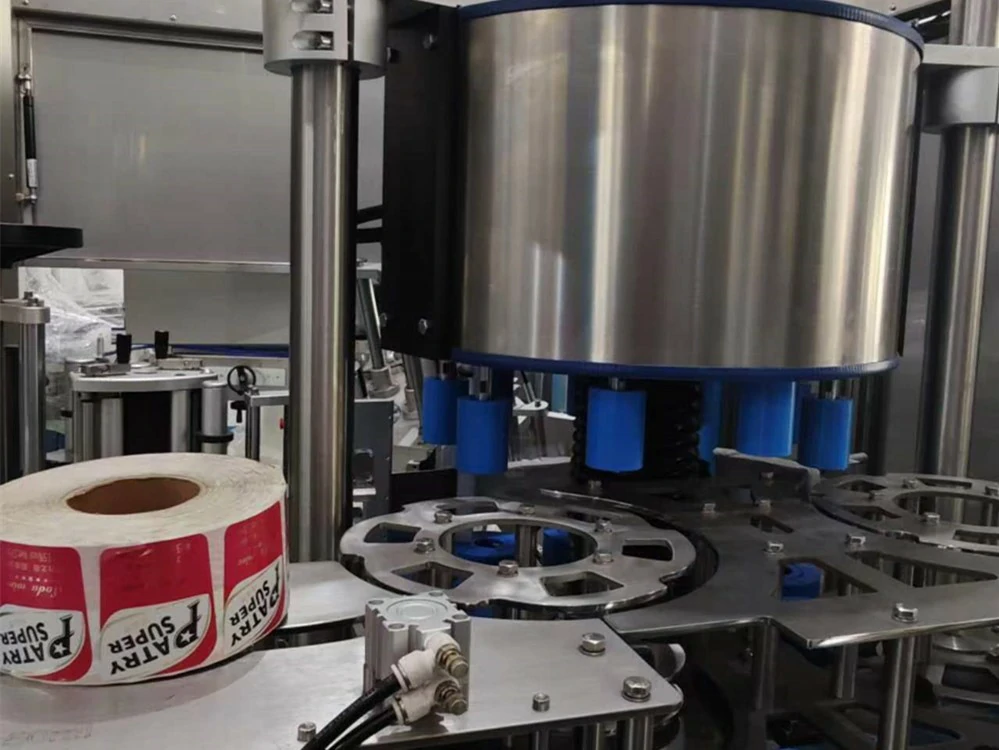

Automatic Linear Type Hot Glue Labeling Machine

- Category:Labeling Machine

Automatic linear type OPP labeling machine is used in continuous roll label sticking on bottles by hot glue. It uses local glue spraying method. It consumes less glue and has low running cost. The maximum speed is 600BPM, which is mainly suitable for high-level drinking water and soft drink.,etc production.OPP labeling machine working more high speed and quiet, low glue consumption, compare with shrink label, its lower cost in material. Tip : You can obtain the price for individual equipment as well as solutions for the entire production line

- Inquiry Email

Equipment introduction:

1. Equipment composition

A: Host

France Schneider servo system

France Schneider servo drive system

France Schneider motion controller

Germany Siemens color screen human-machine interface

Japan Panasonic high-speed high-resolution color label sensor

B: Mechanical part

Host conveying mechanism: 1500W AC motor (with reducer), inverter speed regulation;

Conveying mechanism: 750W AC motor (with reducer), inverter speed regulation; industrial nylon chain conveyor belt

Bottle separation mechanism: industrial screw bottle separation mechanism

Bottle feeding mechanism: with screw bottle separation mechanism, star wheel positioning feeding mechanism, to ensure the accuracy and stability of feeding

Positioning mechanism: mechanical pre-positioning; using cam mechanism trajectory to flatten bottle positioning labeling

Labeling mechanism: rotating turntable drives bottle, labeling during rotation

Labeling mechanism: high-speed servo label film labeling system (high-speed servo motor drive)

Labeling mechanism: professional arc brush assembly

Bottle guiding mechanism: profile guide rail with dual coordinate adjustment

2. Equipment safety protection part

Safety protection: When the equipment is running, close the protection door to prevent harm to the operator

Label shortage alarm: Set an alarm when the label is about to run out to remind the operator to prepare to replace the label

Bottle shortage alarm: When there is a bottle shortage, the equipment stops and alarms; when there is a bottle, production is automatically resumed to facilitate online production

Missing label alarm: It is conducive to the control of labeling quality

3. Labeling working principle

This labeling machine is a new type of rotary labeling machine with continuous operation; the equipment can automatically adjust the in and out transmission of the container; the container conveyed by the conveyor belt is separated by a certain distance according to the spacing of the star wheel by the bottle separation screw, and then the imported star wheel conveys the container to the container turntable. After the container is fixed by the bottle pressing mechanism and the mold seat of the container, the container begins to rotate at a certain speed; the product is mechanically pre-positioned during the rotation process; and the positioning and labeling are carried out according to the mechanism trajectory. When the container reaches the electric eye detection position, the computer host controls the label delivery system to deliver the label.

When the label is transferred to the labeling position, the label can be accurately and effectively adhered to the container. Since the container is in a rotating state during the label transmission process, the label can be smoothly and tightly adhered to the container.

The whole process is: bottle feeding - pre-positioning - labeling - label support - pressing - completion

4. Technical parameters:

Three-phase 380V 50 Hz 8000W

Total length of equipment: 3615mm (conveyor belt length of labeling machine: 3615mm; can be adjusted according to the actual size of the customer's production line)

Equipment width: 2500mm

Conveyor line speed: 30 meters/minute (conveyor line speed can be adjusted according to actual production conditions)

Speed adjustment method: stepless speed regulation

Labeling speed: Labeling speed 150 meters/minute

Labeling speed: 18,000 bottles/hour (production speed can be adjusted according to actual conditions)

Labeling accuracy: ±1mm

Labeling accuracy: ±1mm

Product size: 550ml

Label width (height): 150mm (standard width, width can be increased according to actual product size)

Label length: 500mm

Label outer diameter: 600 mm

Paper core diameter: 152mm

Label type: self-adhesive

Number of labeling molds: Standard configuration is 1 set (based on the 1 specification product provided, each set of molds includes bottle inlet screw, bottle inlet star wheel, bottle outlet star wheel, positioning bottle holder, etc.)

Labeling product type: round bottle

Machine weight: about 3000 Kg

INQUIRY

CATEGORIES

CONTACT US

Name: General Manager

Mobile:+86 188 6222 6180

Whatsapp:+86 188 6222 6180

Email:libby@kingbestmachine.com

Add:No.3 Jinxiu Road, Jiangsu Yangtze International Metallurgical Industrial Park, Jinfeng Town, Zhangjiagang, Jiangsu, China