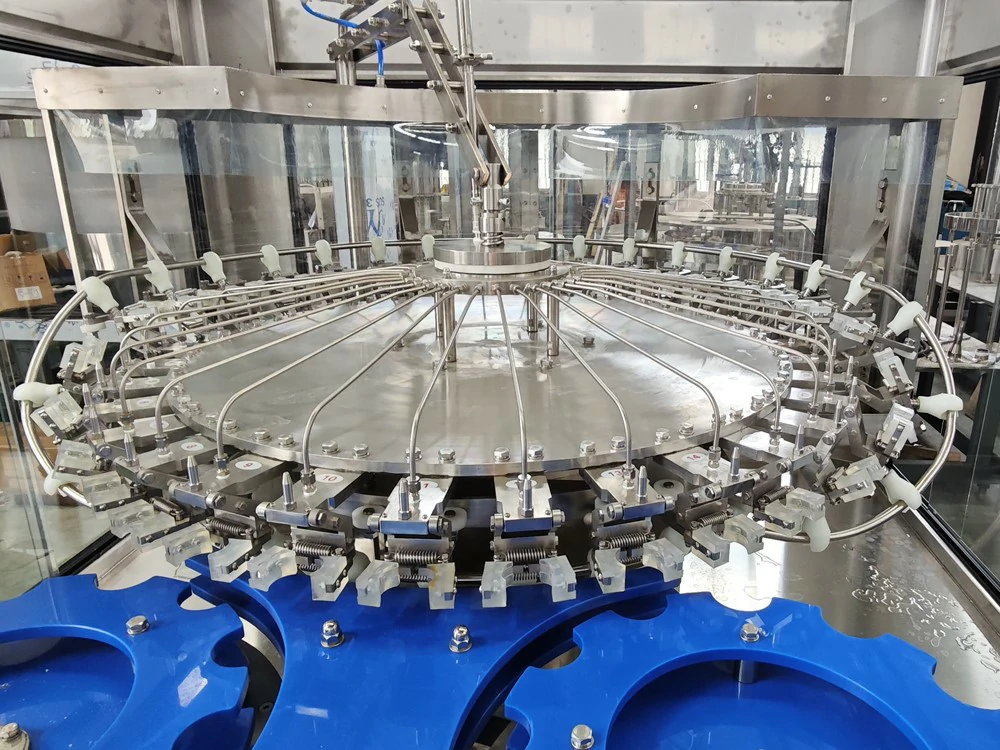

Automatic Small Bottle Pure Water Filling Machine

- Category:Water Filling Machine

The KBM water filling three-in-one machine integrates rinsing, filling and capping. It is developed based on foreign advanced technology and according to the filling process requirements of different beverages.

- Inquiry Email

▼ Overview

The KBM water filling three-in-one machine integrates rinsing, filling and capping. It is developed based on foreign advanced technology and according to the filling process requirements of different beverages. It can meet both normal temperature and hot filling filling equipment, and has a complete CIP cleaning function. It is suitable for water and conventional hot filling beverage filling and packaging. It is a kind of filling equipment with domestic advanced level.

▼ Working process

The bottle is transmitted by the air conveyor and sent to the rinser of the three-in-one machine through the bottle star wheel. The bottle clamp is installed on the rotating disk of the rinser. The bottle clamp clamps the bottle mouth and turns 180° along the guide rail to make the bottle mouth face down. In the specific area of the rinser, the rinser nozzle sprays rinsing water to rinse the inner wall of the bottle. After rinsing and draining, the bottle is clamped by the bottle clamp and turned 180° along the guide rail to make the bottle mouth face up. The washed bottle is guided out of the rinser through the bottle star wheel and sent to the filling machine. The bottle entering the filling machine is clamped by the bottleneck clamp installed on this lifting device. The bottle mouth rises under the action of the cam and contacts the filling valve, and then the filling valve is pushed open by the bottle mouth. The filling adopts the method of micro-negative pressure and gravity filling. After the filling valve is opened, the material passes through the filling valve to complete the filling process. After the filling is completed, the bottle mouth leaves the filling valve under the action of the downward pressure cam, and the bottle enters the capping machine through the bottleneck transition dial. The anti-rotation knife on the capping machine clamps the bottleneck part to keep the bottle upright and prevent rotation. The capping head keeps orbiting and rotating on the capping machine, and realizes the actions of grabbing, covering, screwing and removing the cap under the action of the cam to complete the entire capping process. The finished bottle is transferred from the capping machine to the bottle conveyor chain through the bottle discharge dial, and is conveyed out of the three-in-one machine by the conveyor chain.

▼ Equipment Features

1. The machine has a compact structure, a complete control system, convenient operation and a high degree of automation.

2. The parts in contact with the material are made of high-quality stainless steel, which is corrosion-resistant and easy to clean.

3. High-precision, high-speed quantitative filling valve is used, the liquid level is accurate and there is no liquid loss, ensuring excellent filling quality.

4. The capping head adopts a constant torque device, which ensures the capping quality and will not damage the bottle cap.

5. An efficient cap sorting system is adopted, with perfect cap feeding and protection devices.

6. A perfect cleaning management system is set up to ensure the flushing quality before filling.

7. To change the bottle shape, you only need to replace the star wheel, bottle feeding screw and arc plate, which is simple and convenient to operate.

8. A perfect overload protection device is set up to effectively protect the safety of the machine and the operator.

9. This machine adopts a variable frequency speed regulation motor, which can easily adjust the production capacity appropriately.

10. The main electrical components, frequency converters, photoelectric switches, proximity switches, electric control valves, etc. are all imported components to ensure the excellent performance of the whole machine.

11. The control system has functions such as automatic water level control, cap shortage detection alarm, bottle flushing automatic stop alarm and shift production counting.

12. All components of the gas system are imported products.

INQUIRY

CATEGORIES

CONTACT US

Name: General Manager

Mobile:+86 188 6222 6180

Whatsapp:+86 188 6222 6180

Email:libby@kingbestmachine.com

Add:No.3 Jinxiu Road, Jiangsu Yangtze International Metallurgical Industrial Park, Jinfeng Town, Zhangjiagang, Jiangsu, China